When it comes to fracture surgery, the choice of screws can make or break the success of the procedure. With multiple types of screws available, each offering unique properties, understanding their applications and limitations is critical for achieving optimal outcomes. This article explores the different types of surgical screws, their functions, advantages, and potential pitfalls, providing surgeons with a detailed guide to make informed decisions.

Mono-Cortical Screws: Advantages and Limitations

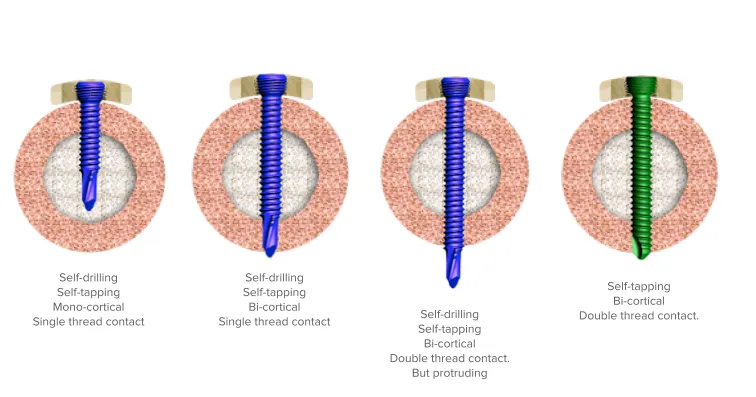

Mono-cortical screws are widely used in fracture surgery due to their ease of application and good pull-out resistance. These screws penetrate only one layer of cortical bone, making them less invasive than their bi-cortical counterparts. However, their utility is not without controversy.

Key Features of Mono-Cortical Screws

- Good pull-out resistance: These screws anchor securely in the near cortex, providing stability in many surgical scenarios.

- Length flexibility: The tip of the screw can protrude into the medullary cavity without causing complications, making precise length measurement less critical.

- Weak tilting resistance: Due to a shorter lever arm, mono-cortical screws are susceptible to tilting under torque or bending forces applied to bone fragments or plate constructs.

- Threading options: Available in self-threading or self-drilling designs, they offer versatility in application.

When to Use Mono-Cortical Screws

While mono-cortical screws have specific advantages, their poor resistance to tilting limits their use in high-stress areas. Surgeons should weigh these factors carefully before selecting them for fracture fixation.

Bi-Cortical Screws: Enhanced Stability for Complex Cases

Bi-cortical screws penetrate both the near and far cortices, providing superior stability compared to mono-cortical screws. Their design ensures greater resistance to tilting and bending forces, making them ideal for high-stress fractures.

Why Choose Bi-Cortical Screws?

- Increased tilting resistance: The lever arm corresponds to the bone’s outer diameter, significantly enhancing stability.

- Thread contact options: These screws can achieve single or double thread contact in the far cortex, depending on the surgical requirements.

- Versatility: Bi-cortical screws are suitable for various fracture types, including those requiring robust fixation in weight-bearing bones.

Potential Drawbacks

While bi-cortical screws offer excellent stability, their insertion requires precise length measurement to avoid soft tissue protrusion, which can lead to complications.

Self-Drilling and Self-Tapping Screws: Simplifying Surgery

The advent of self-drilling and self-tapping screws has revolutionized fracture surgery, allowing for faster and more efficient procedures. These screws eliminate the need for pre-drilling, reducing surgical time and enhancing precision.

Benefits of Self-Drilling Screws

- Quick application: Their self-drilling tips create a precise bone thread, streamlining the fixation process.

- Biological safety: Modern designs minimize the risk of biological loosening, a concern with earlier iterations.

Challenges in Application

- Axial resistance: Self-drilling bi-cortical screws can experience high axial resistance, potentially stripping threads in the near cortex.

- Length measurement: Determining the exact screw length can be challenging without pre-drilling, increasing the risk of improper fixation.

Application Tip

To avoid issues like thread stripping, pre-drilling with a drill bit slightly smaller than the screw’s core diameter is recommended. This technique ensures smooth advancement and accurate length measurement.

Locked Screws: Revolutionizing Fracture Fixation

Locked screws are a game-changer in fracture surgery, offering unparalleled stability by coupling the bone and plate like bolts. Unlike conventional screws, their primary function is not to generate axial force but to maintain a fixed distance between the bone and plate.

Advantages of Locked Screws

- Enhanced stability: These screws provide a stiff elastic coupling, promoting reversible fracture movement that stimulates healing.

- Uni-cortical compatibility: Locking is a prerequisite for using mono-cortical screws, making them a versatile option for various constructs.

Fixed Angle vs. Variable Angle Locked Screws

- Fixed Angle Locked Screws (FAL): Require perfect alignment with the screw hole axis, offering solid coupling but limited flexibility.

- Variable Angle Locked Screws (VAL): Feature a spherical thread design, allowing for a 15-degree range of inclination, making them more forgiving and adaptable.

Clinical Considerations

While locked screws are generally reliable, clinical observations show potential for unlocking under repetitive loading. Surgeons must monitor for signs of failure during follow-up.

Lag Screws: Precision in Fracture Compression

Lag screws are specifically designed to compress fracture fragments, promoting absolute stability and primary healing. However, their effectiveness depends heavily on optimal positioning.

Indications for Lag Screws

- Long oblique or spiral fractures: These screws are highly effective in compressing long fracture lines.

- Protected compression: Combining lag screws with a protective plate ensures load-sharing and prevents thread stripping.

Limitations

Lag screws are not suitable for short oblique or transverse fractures, as they may fail to provide adequate compression. Additionally, suboptimal placement can compromise their function, particularly in minimally invasive procedures.

Potential Pitfalls and Complications

Despite their advantages, surgical screws are not without risks. Common issues include:

- Thread stripping: Often occurs with self-drilling screws if pre-drilling is not performed.

- Loosening: Can result from bone resorption at the screw-bone interface or mechanical overload.

- Jamming: Locked screws may become jammed due to bone ingrowth, complicating removal.

- Loss of angular stability: Fixed angle screws lose stability if misaligned by more than 2 degrees.

Preventive Strategies

- Pre-drill when necessary to avoid thread stripping.

- Use advanced imaging to ensure proper screw placement.

- Opt for variable angle screws in cases requiring flexibility.

Disclaimer:

This article and all articles on this website are for reference only by medical professionals; specific medical problems should be treated promptly. To ensure “originality” and improve delivery efficiency, some articles on this website are AI-generated and machine-translated, which may be inappropriate or even wrong. Please refer to the original English text or leave a message if necessary. Copyright belongs to the original author. If your rights are violated, please contact the backstage to delete them. If you have any questions, please leave a message through the backstage, or leave a message below this article. Thank you!

Like and share, your hands will be left with the fragrance!